|

|

Post by nikeajax on Oct 17, 2016 9:55:10 GMT -8

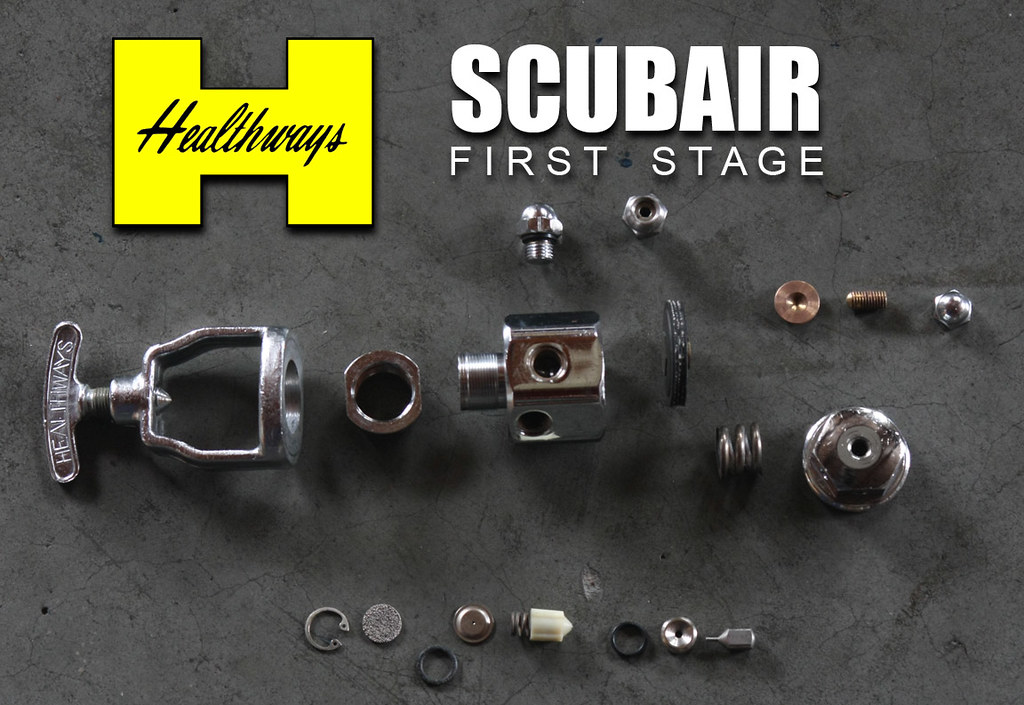

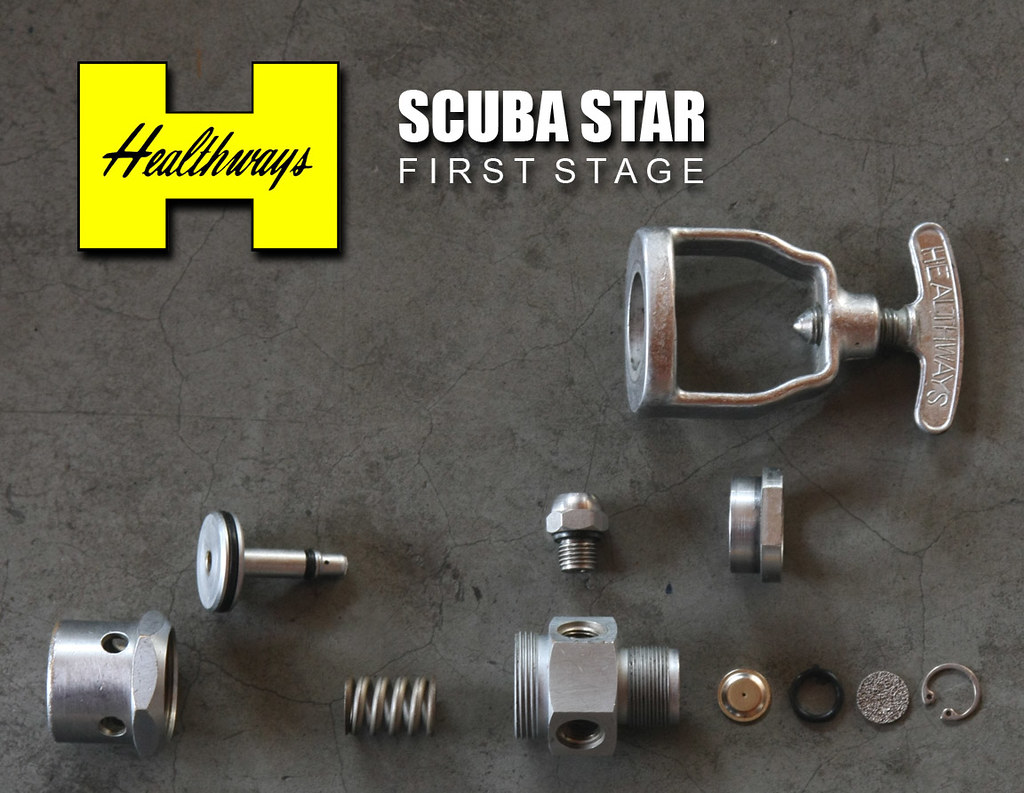

PLEASE NOTE: This is a work in progress and I will be updating and editing these posts; please wait to comment  Healthways first single hose regulator, the Scubair model 1665 was introduced in 1960 and ended in 1961. Their second SH reg. the Scuba Star model 1664, as originally configured, was produced from 1961 to 1966. The second stages were identical: as with most single hose regs of the time, they were tilt-valves. What differentiated the two were the first stages.  The Scubair was an unbalanced diaphragm regulator and used the very same principals as their earlier double hose Scubas: it also used some of the same parts, like the nylon valve-plunger, or the same parts were modified, as in the case of the actuator/push-rod.  The Scuba Star on the other hand was a complete departure: it was a very simple unbalanced "flow-by" piston regulator. This design proved to be so robust that all subsequent Healthways single hose regulators beginning in 1962 were based on and around it. The Scuba Star was sold by Healthways for 20-years, throughout their single hose period, virtually unchanged except for the addition of a high-pressure-port for using and SPG (submersible pressure gauge). JB

|

|

|

|

Post by nikeajax on Oct 17, 2016 11:16:14 GMT -8

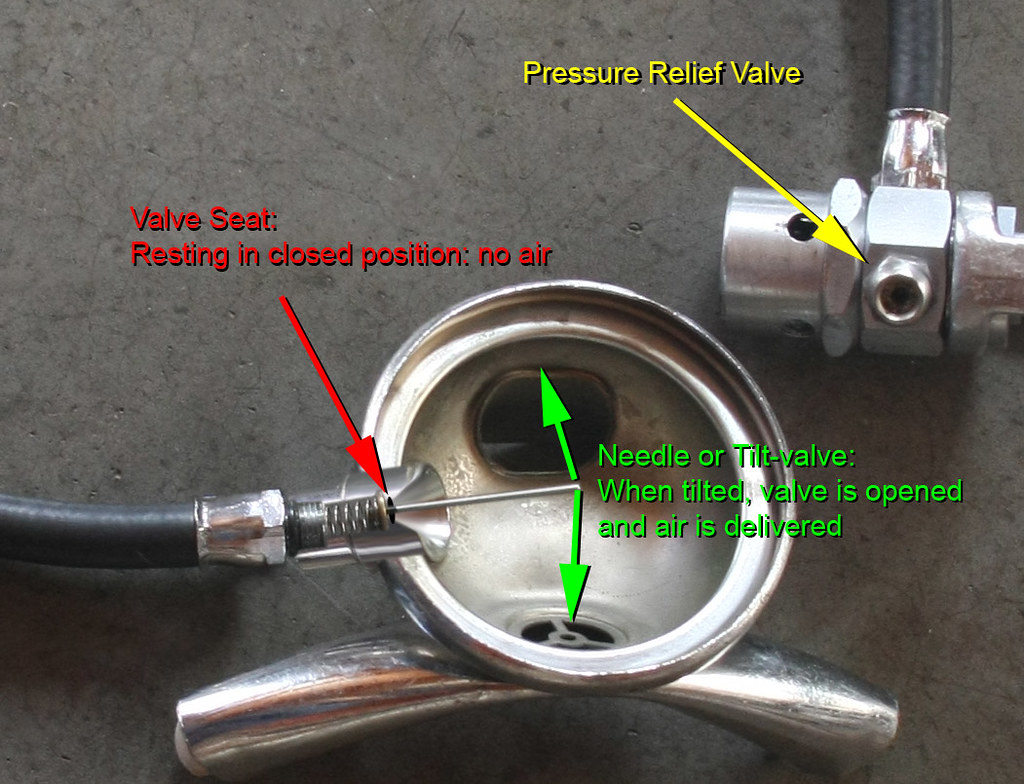

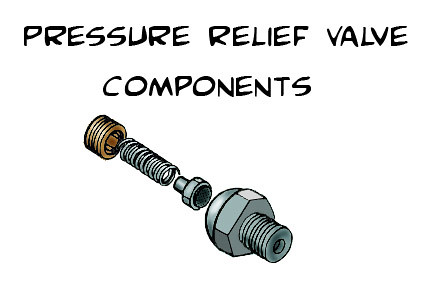

Tilt-valve second stages:As mentioned above, the first generation of Healthways single hose regs used a simple up-stream-tilt-valve, but because of simplicity of the design, it is not adjustable, it also needed a safety feature in case too much pressure was built up behind the valve; this was a pressure relief valve.   The way the tilt valve works is that a light spring is used to hold the soft seat of the tilt/needle valve against the metal valve seat, or volcano orifice. Air pressure is also used to hold the valve in place. This kind of valve work exactly like a lever and fulcrum: the long needle end sticks out and touches the diaphragm-plate. When the diver inhales, the vacuum that is created, draws the metal diaphragm plate inward causing the needle valve to tilt, thus opening the valve and air passes through the volcano orifice delivering air to the diver. The safety feature:Because air pressure helps hold the valve closed, it is vital that some sort of venting be used in case of high pressure valve seat failure. Unlike the adjustable down stream valve which will free flow at the second stage if the HP-seat fails, the up stream/tilt valve will lock up tight unable to vent, using all of the air pressure inside the tank to seal the valve shut. Without venting the low pressure second stage hose can burst: it is some times stated on the side of these hoses not to exceed 250-psig.  The PRV, pressure relief valve, is adjustable so that it can be set to open at a given maximum PSI. The PRV is held closed by a spring, and is adjusted by varying the tension on the spring. To adjust said PRV you use an Allen-wrench to turn the threaded adjuster in the valve body. If then the HP seat fails, the the free flow will occur at the PRV and not the second stage. JB

|

|

|

|

Post by tomcatpc on Oct 17, 2016 11:54:59 GMT -8

Been looking forward to this, glad it is started!

Mark

|

|

|

|

Post by nikeajax on Oct 17, 2016 16:15:27 GMT -8

Examples of early Healthways second stages:  A few things to notice here: the Scuba Star is painted blue, these were the 1960-models. The Scubair is chrome, these were the 1961-models. Also notice the black rubber plug for access to the exhaust/mushroom valve and the "quick clip"; this was HW's method for securing the the top cover. The purge button on the tilt valves was flat, later models were domed, or convex... JB

|

|

|

|

Post by diverdon on Oct 18, 2016 0:58:14 GMT -8

Very nice, JB. I too am glad you started this thread. Good to see 'ol Bloo in there as well. Love that color!

DD

|

|

|

|

Post by nikeajax on Oct 18, 2016 12:49:20 GMT -8

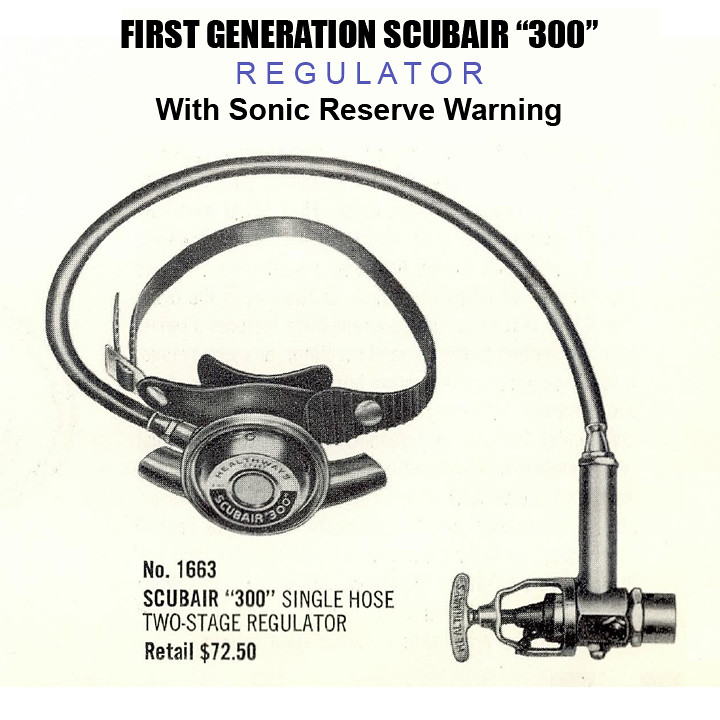

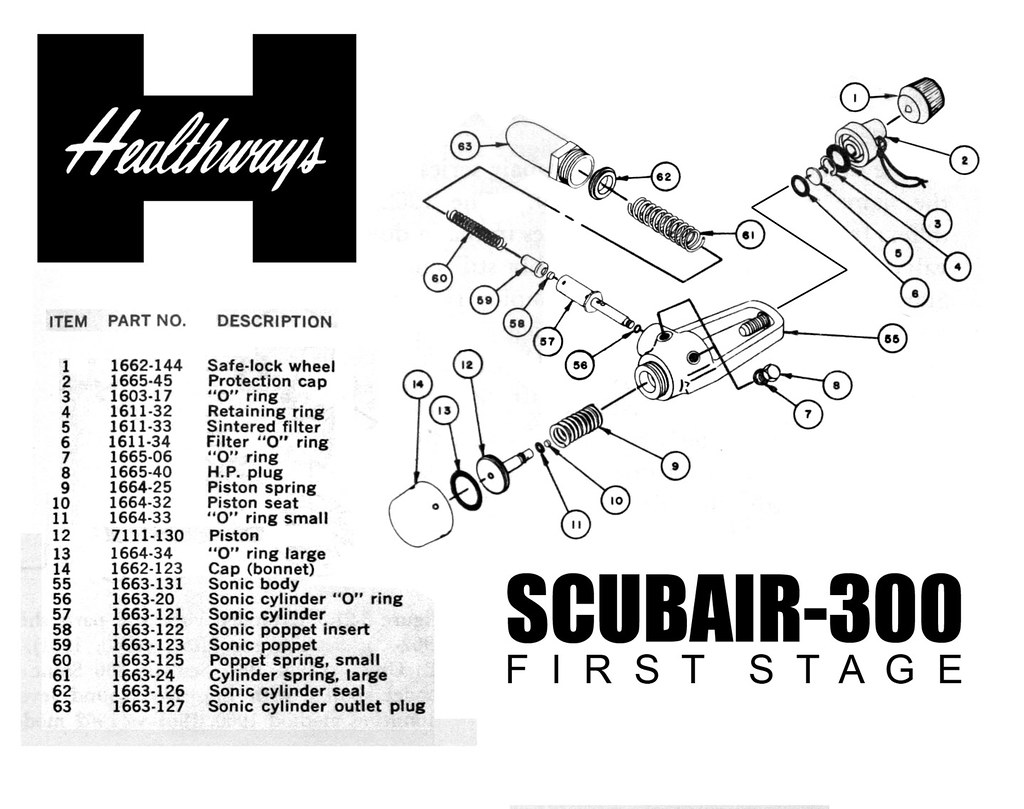

In 1961, the Scubair-300 was first introduced: it was essentially a Scuba Star with an audio-warning device added to it. I should mention these first models were also tilt-valves. Here is an image of Mark's with a down-stream-valve attached:   Here is an exploded view of the 1962 model from Basic Scuba (please note that I have separated the image from the book to show clarity)  Fred Roberts’ book, “Basic Scuba” describes it here: Scubair "300"

Single Hose; Two Stage: High Pressure Stage—Piston Type;. Demand Stage-Downstream Push-Pull Type.

The Scubair "300" employs the same first stage piston assembly as the Scubair and Scubair "J" and high pressure end parts, refer to Figure 3-20. Between the demand stage and the intermediate stage, however, is a mechanism, introduced in 1961, intended to sound an audible warning when the air supply reached a predetermined pres¬sure level. The device can be heard pressurizing, characterized by a thump when the air is first turned on before the dive, and a just audible thump may be heard each time a breath is taken when pres¬sure in the cylinder falls to about 300 psig. The noise of the 1962 model is easy to hear, but the 1961 model leaves much to be desired, either to a diver who is slightly hard of hearing or who is preoccupied. Mechanically the device consists of two coaxial pistons and springs in a housing attached to the body yoke (55), Figure 3-21.

Before pressurization of the stage by opening the cylinder valve, both the sonic poppet spring (60), Figure 3-20, and the cylinder spring (61) hold their respective parts toward the stage body assembly. When the high pressure air is turned to "on," it flows through the filter assembly and the yoke end of body (55) and into the regulated portion of the piston chamber, the small end of the piston. From the piston seat, downstream of the air source, the air flows into the sonic device where the demand stage hose would normally be attached to the stage. The end of sonic cylinder (57) is exposed to upstream cylinder pressure on one side of sonic "O" ring (56) and interstage pressure on the other, causing the cylinder to move in the lowest pressure direction compressing cylinder spring (61) in the process. When the cylinder (57) retreats from seat (62), it allows unrestricted passage of air to the demand stage system already described under Scubair (1962). Poppet (59) oscillates during this portion of the cycle, but does not take over until low cylinder pres¬sure allows sonic cylinder (57) to retreat toward seat (62) via spring (61) near the end of the dive.

When cylinder pressure decreases to warning range, cylinder (57) has been forced toward body yoke (55) by spring (61), and seals on seat (62) along the perifery of a machined shoulder. Air now must flow through the small by-pass hole in the stem of cylinder (57) and lift poppet (59) against spring (60) with an initial thump. Flow is sufficient during demand to allow air to leak around cylinder (57) as well as by poppet (59) until demand lock-up. Then with pressure equalization in the intermediate section of the stage, spring (60) re¬turns the poppet valve (59) to its seat in cylinder (57). Now each time the demand process is repeated a thump will be heard at the beginning of the inhalation—a time when considerable air noise is also present.

The demand stage of the Scubair "300" is identical to that of the Scubair and Scubair "J" except for the name plate. See demand stage under Scubair (1962) for operation.

1962 first stage: JB |

|

|

|

Post by tomcatpc on Oct 18, 2016 20:59:29 GMT -8

Can I share a link to this and the Healthways Double Hose topic on my Facebook page for Healthways?

Mark

|

|

|

|

Post by nikeajax on Oct 19, 2016 7:33:04 GMT -8

Absolutely  JB |

|

|

|

Post by nikeajax on Oct 20, 2016 12:27:22 GMT -8

|

|

|

|

Post by nikeajax on Oct 21, 2016 9:27:07 GMT -8

Before we continue with the new 1962 models, I thought I’d point out a few of things. The clean design of the second stage was like that of the German-Bauhaus-style: en.wikipedia.org/wiki/BauhausOne of the things in the Bauhaus school of thought was “form follows function”. If you compare this regulator to any other you will notice that it has a snag-proof purge button, most, if not all other regulators had a purge button that stuck way out: in the mid-1960’s nearly everyone else adopted this feature. Something else that Healthways did was channel the exhaust gasses back and away from the diver’s mask with a long metal exhaust-tee. This was by no means a perfect design, it was restrictive. Dacor also used an exhaust like this on their Dart, but theirs was rubber. The idea behind this was to keep the diver’s mask clear of bothersome bubbles obstructing their view and at times causing mask bounce: this is where the air bubbles are causing the mask to shutter and bounce on exhalation. JB |

|

|

|

Post by SeaRat on Oct 21, 2016 11:29:24 GMT -8

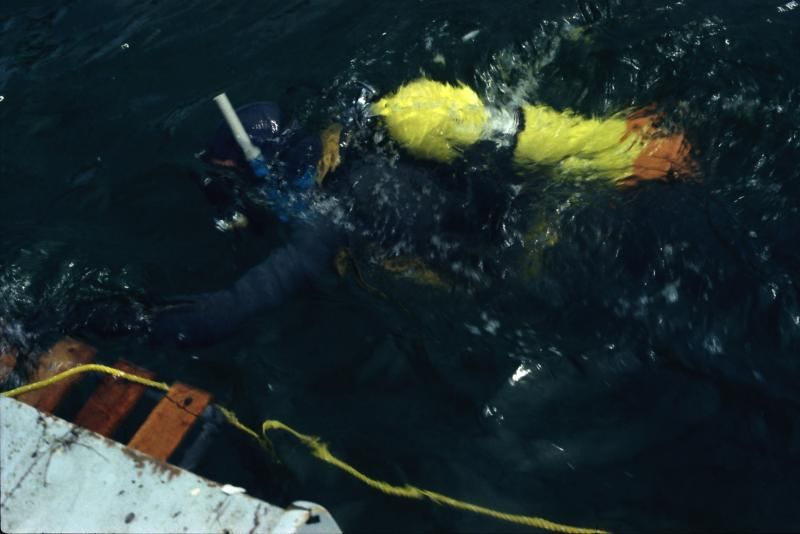

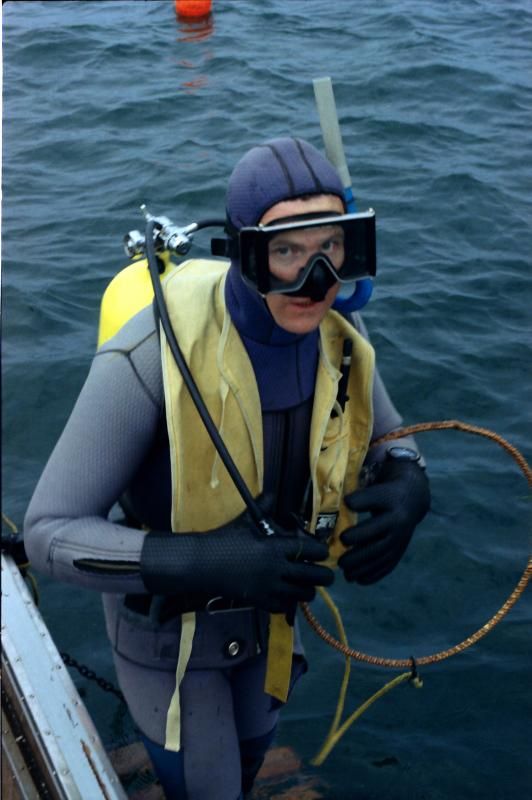

Jaybird makes some interesting observations above, and I would like to amplify some of his points from the perspective of a diver who lived through this era. Healthways was forced to innovate by U.S. Divers Company and Voit, who at that time had identical products (with very minor exterior changes. I went away from Healthways to the Voit Viking 40 Fathom regulator (original Calypso) which had a downstream second stage. They advertised that any second stage which featured a tilted valve (LP air coming into the second stage at an angle, rather than straight in) was a tilt valve, and therefore inferior to the downstream valve featured in their regulators. Obviously, both Healthways and Sportsways featured this type of valve. So to counter this advertising blitz, Healthways came out with its 1962 regulator line. The Calypso was also suffering from diver's experiences in high current where the current actually opened the exhaust in the diaphragm of these regulators, and flooded the second stage. I don't recall this happening to me on dives in Oregon rivers or currents in Yaquina Bay, but do remember it being a wetter breathing regulator than the Healthways Scuba Star I started out with for my first single hose regulator in about 1962. This gives perspective to the Healthways double exhaust, which effectively eliminated this possibility. This probably also caused USD to redesign their second stages to eliminate the exhaust in the diaphragm and make a regulator with an exhaust "T" too. We in the USAF used the second generation Calypso for years, even though the U.S. Navy refused to approve this regulator due to exhaust resistance. Realize that old school divers were not so concerned about breathing ease at that time, and preferred Healthways due to the design, accessibility, robustness, and affordability of their line over most others. Now, 54 years later, we still see fully functional Healthways regulators on the used market, which is a testimony to their design. John  Biologist Limons Osis surfaces from a rigorous dive in Yaquina Bay in 1975, using his Scubair regulator.  Limons Osis with his Scubair regualor preparing for his sub-tidal clam bed survey dive. |

|

|

|

Post by nikeajax on Oct 21, 2016 12:31:56 GMT -8

From the perspective of a diver who lived through this era. Healthways was forced to innovate by U.S. Divers Company and Voit, who at that time had identical products (with very minor exterior changes... Now, 54 years later, we still see fully functional Healthways regulators on the used market, which is a testimony to their design. John Another innovation was the demand valve had a portion of the shaft that was square where it went through the valve body to keep it from turning while adjustments are made in tuning the second stage; see image:  Unlike the US Divers valve which turns/spins freely, thus requiring a small screw driver as well as a 1/4" wrench to tune the regulator: tuning USD second stages can be a bit trying at times... JB |

|

|

|

Post by SeaRat on Oct 23, 2016 17:20:37 GMT -8

I now have my "new" Scuba Star first stage in the "drink" of acetic acid (white vinegar) that I picked up for $8.00. Looking on E-Bay, I thought it might be gold-plated, as it had that look in the photo. Nope, but that's okay as I was the only bidder, and it will give me both a tilt-valve version of the Scuba Star and a downstream version of the same named regulator.

The first stage is now out of the acid bath (except the sintered filter, which I will give more treatment, and the body, which was extremely dirty as well as having some corrosion).

I have an additional observation. That is that the body of this first stage has only one low pressure outlet, whereas my tilt valve Scuba Star had two (one for the LP hose, and one for the overpressure relief valve). So when Healthways made the change to a downstream second stage, on their low priced first stage (the Scuba Star), at least initially there was no provision for more than the second stage so far as low pressure outlets goes. That would make the Scubair and its cousins more attractive.

John

|

|

|

|

Post by tomcatpc on Oct 23, 2016 22:10:43 GMT -8

I dove my Scubair today. Had two fun short dives, now that I have three working Healthways single hose regs, plus the SCUBA, it is getting to the point where I have to decide which I want to dive the most. Liking the Scubair 300, but wanted to dive the Scubair as much as I can to get used to it.

I can see changing the exhaust valves in it soon, probably a good mid-Winter project.

Mark

|

|

|

|

Post by nikeajax on Oct 24, 2016 12:03:34 GMT -8

|

|