Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jul 27, 2019 13:13:57 GMT -8

Phil,

I don't know your ID of the cone, but if you make it 0.196-0.201 ID you'll get a vastly improved air flow.

|

|

|

|

Post by vance on Jul 27, 2019 14:14:40 GMT -8

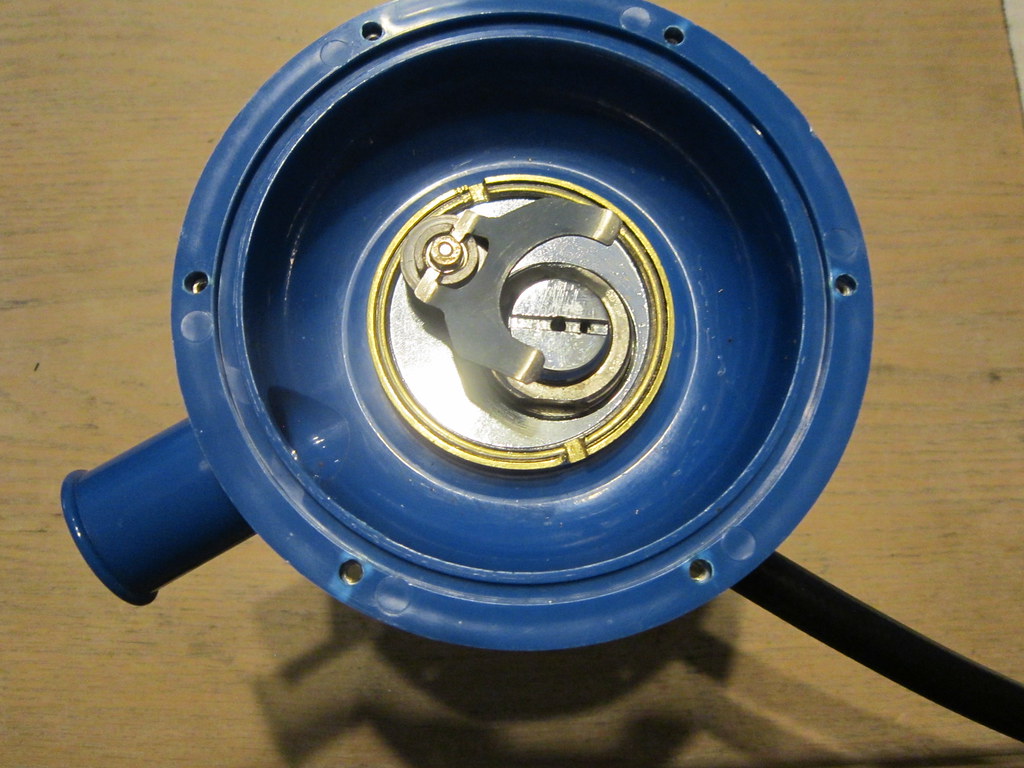

Lever height is perfect. It's just about ready to make bubbles. I am still thinking on a venturi tube or air director.  Yup. It's a Dacor!  |

|

|

|

Post by technidiver on Jul 27, 2019 16:18:10 GMT -8

Looks great Phil!!! Say, couldn’t you tap a hole and use a Mistral Venturi? Would that work?

TD

|

|

|

|

Post by nikeajax on Jul 27, 2019 16:22:26 GMT -8

Phil, I'm really glad you didn't give up-- BRAVO GOOD SIR! As of late I've been geeking out on vintage fishing gear, 1940's-50's... JB EDIT: I've got some Dacor cans and a 400 I really want to do this to... |

|

|

|

Post by vance on Jul 27, 2019 17:00:58 GMT -8

Looks great Phil!!! Say, couldn’t you tap a hole and use a Mistral Venturi? Would that work? TD Thanks, TD. There's a couple directions to go here. I'm planning to make a brass cap in place of the delrin piece. Then, I'll drill and tap, or drill and solder, for a venturi tube. A Mistral tube might be the thing! The other idea is to use a rectangular block, like Herman did, which brings the second stage hole closer to the intake air horn. This has the advantage of making room for an adjustable venturi, which Herman added, that uses a carburetor style setscrew to adjust airflow. That's kew! Dunno yet, as there's a lot to do before taking it into the pool. I was on the verge of thinking I couldn't do this project with my limited machine tools and skillz, but I'm getting closer! I need to make a new, longer nipple, mod a USD type seat carrier, make a new brass cap, and f' around with getting air to the intake horn. |

|

|

|

Post by vance on Jul 27, 2019 17:03:43 GMT -8

Phil, I'm really glad you didn't give up-- BRAVO GOOD SIR! As of late I've been geeking out on vintage fishing gear, 1940's-50's... JB EDIT: I've got some Dacor cans and a 400 I really want to do this to... I was close to despair. But, things become clear if you think on 'em enough. There'd be a fair amount of work to do on Dacor cans for them to work with this mod. |

|

|

|

Post by vance on Jul 28, 2019 8:11:21 GMT -8

I'm eyeballing a pair of orphan Scuba Deluxe cans for this project. The top can is not too good, being pitted and kinda crappy looking. I wouldn't mind chopping a huge old hole in it for the Dacor body. The bottom can is better, and it doesn't need to be modded, so no harm there.

I'll need to measure for lever height and all before deciding. I'd love to use a Scuba can set for its svelte figure, but that exhaust set-up.....

|

|

|

|

Post by technidiver on Jul 28, 2019 10:22:11 GMT -8

Phil I’m not sure if I’ve asked this, but if one were to use a DAAM second stage or the HPR, could you bend the lever to make it fit?

As for the cans, does it matter which ones you use for height? I figured most were about the same height.

TD

|

|

|

|

Post by vance on Jul 28, 2019 10:47:07 GMT -8

Phil I’m not sure if I’ve asked this, but if one were to use a DAAM second stage or the HPR, could you bend the lever to make it fit? As for the cans, does it matter which ones you use for height? I figured most were about the same height. TD Differences in cans and diaphragms can cause problems. Not all valves protrude into the can the same amount, some have compound levers, etc. I don't think you can assume any combination will work together. The DAAM/HPR approach requires a bigger hole in the first stage than I am comfortable with, breakout-wise. The DAAM requires a complicated lever arrangement, also. The HPR would be the way to go, if it could fit, but you still have the venturi problem. Looking at my mod, I began to think that the drilling could be positioned so the second stage body is closer to the air horn. The hole in mine is 1/2", not 5/8", so there' a bit of leeway, but you still run out of real estate for the hole rapidly. Also, the levers would be off center a bit. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Jul 28, 2019 14:22:32 GMT -8

Ok< I guess I am missing something here. Reviewed all the posts and still do not understand what cans are you using? They look to be of plastic.....are they USD? Additionally, I do not see any alignment groves cut into the Dacor main body threads? What are you using to align the valve up with and if there is no alignment tabs cut into the valve body, why can you not just point the venturi down the hole.......this is what I am missing.

|

|

|

|

Post by SeaRat on Jul 28, 2019 18:10:45 GMT -8

Ok< I guess I am missing something here. Reviewed all the posts and still do not understand what cans are you using? They look to be of plastic.....are they USD? Additionally, I do not see any alignment groves cut into the Dacor main body threads? What are you using to align the valve up with and if there is no alignment tabs cut intox the valve body, why can you not just point the venturi down the hole.......this is what I am missing. I think the alignment problem has to do with the forged yolk on the Dacor Olympic first stage. That limits where the inhalation hose can go. John |

|

|

|

Post by vance on Jul 28, 2019 22:17:11 GMT -8

Ok< I guess I am missing something here. Reviewed all the posts and still do not understand what cans are you using? They look to be of plastic.....are they USD? Additionally, I do not see any alignment groves cut into the Dacor main body threads? What are you using to align the valve up with and if there is no alignment tabs cut into the valve body, why can you not just point the venturi down the hole.......this is what I am missing. Nope, no alignment tabs or anything. This is kind of a problem for the Titan II conversion as well. The first stage can rotate in the can, which can throw the venturi effect off considerably. But John is correct. The yoke is solid and doesn't rotate, so you are stuck with the second stage at 12 o'clock, or even worse, at 6 o'clock. Also, the angle is bad, so you can't even get a direct shot at the intake horn. The plastic cans are FX 50 Fathom cans borrowed from my Titan II conversion, but I might use the HW Deluxe cans for this. |

|

|

|

Post by vance on Jul 31, 2019 9:23:57 GMT -8

I'm ruminating on the air tube idea for the next second stage cap. This one will be brass, and I think I'll solder a curved tube over the main jet so it fits into the mouth of the intake air horn. This is going to require tuning to get the venturi set. I'd like to incorporate some kind of adjuster to fine tune it.

Another way to go might be to make a block that the cap fits into which extends toward the air horn. I like the extension idea since it could be easily made to have an airflow adjuster screwed in....

|

|

|

|

Post by vance on Aug 1, 2019 16:04:37 GMT -8

I've been making chips again. I just emptied my little vacuum cleaner and poured out 1/2 lb of brass. I wonder how many lbs of chips get dumped every day?

So, I made a new nipple that fits into the bore in the 1st stage and fixed it so it presses the hard seat down tight. It doesn't leak. Next will be a brass cap/lever/seat holder that will get an extension tube soldered onto it. I'm considering several types of venturi adjusters and will do some f'in around with that.

I went to Home Depot today and bought a sink drain pipe that will fit inside a USD straight mouthpiece perfectly. I will fool around with a hose-in-hose setup, since it might be reasonably easy to create the mouthpiece part by gluing the pieces together. Michael's suggestion of a non-return mushroom punched out in the center and held in by the tube and some kind of washery-type retainer might have legs.

|

|

|

|

Post by herman on Aug 1, 2019 17:40:29 GMT -8

I've been making chips again. I just emptied my little vacuum cleaner and poured out 1/2 lb of brass. I wonder how many lbs of chips get dumped every day?

No clue but I have several 2 lb coffee cans full of brass swarf and old hose ends....one of these days I want to start casting aluminum and brass.....after I get a round tooit.

|

|