|

|

Post by nikeajax on Jul 23, 2016 12:23:58 GMT -8

Please note: I will be going back to these posts and re-editing them to try to keep the information accurate!

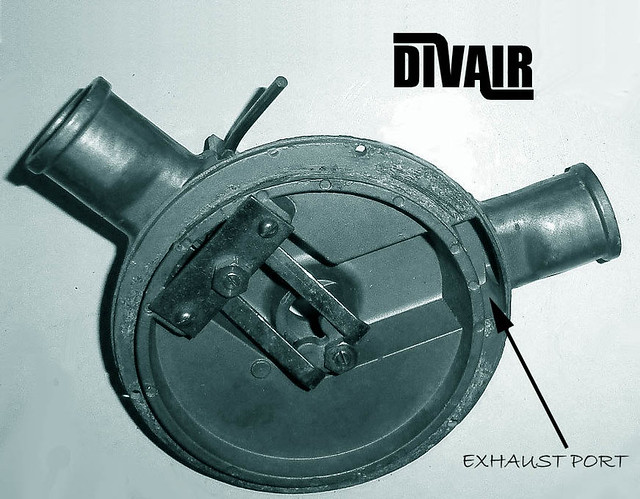

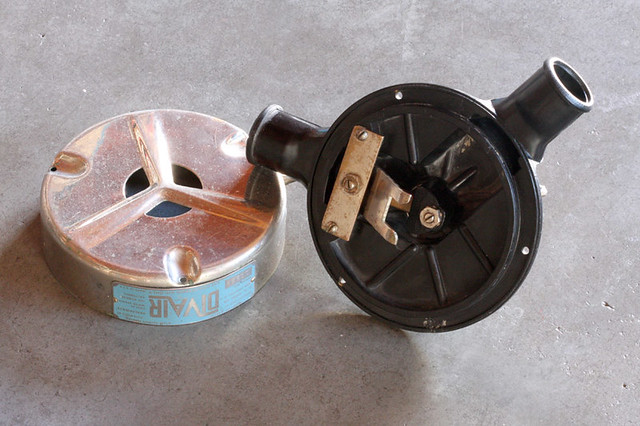

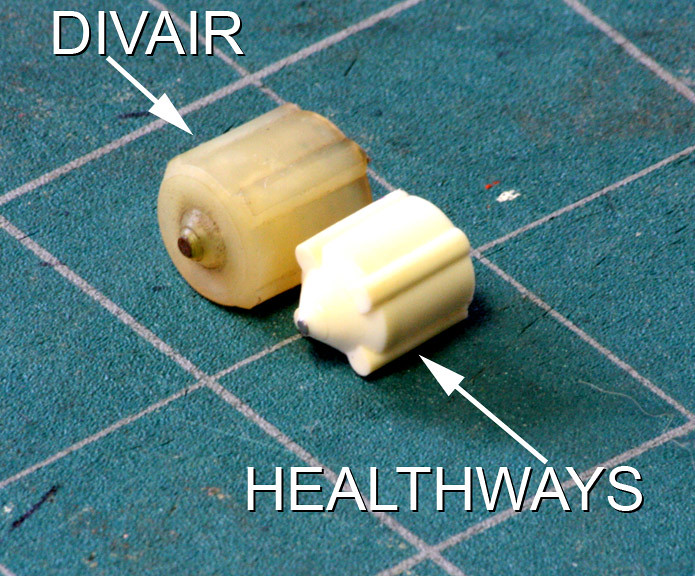

Mark has asked that we start a few Healthways threads to filter out the "wheat from the chaff" as it were. I will try to keep things in chronological-order. Here is my collection:  HW's first started out selling all sorts of sporting goods, everything from golf clubs to pellet guns. Their first regulator was the Divair made by Arpin Industries. I believe it was the first regulator designed and built in the U.S.A.. It also had no exhaust valve so a diver would need to clear his/her hoses periodically. The first A and B models were introduced in 1954 and were quite heavy as they were made from solid nickel plated brass and weighed 2 Lbs. (image needed) The C-models from 1955 were lightened by making them with aluminum: these were quite prone to corrosion!  Models C through F were made from plastic and manufactured from 1955 to 1956:  The Divairs use a unique two lever system as can be seen here:  Later Divairs used the famous Hope-Page non-return valve:   All Divairs used an adjustable reserve valve (not a j-valve) mounted on the right hand side of the regulator: these could be adjusted to give more or less time for the diver when "reserve limit" was met. Divairs used a nylon valve plunger that was copied by HW's designer Sam Lecocq, who took it with him when he founded Sportsways-Water Lung:  Jaybird Please PM me if you have images I can post or if I have made a mistake somewhere and needs to be rectified

|

|

|

|

Post by nikeajax on Jul 23, 2016 13:50:09 GMT -8

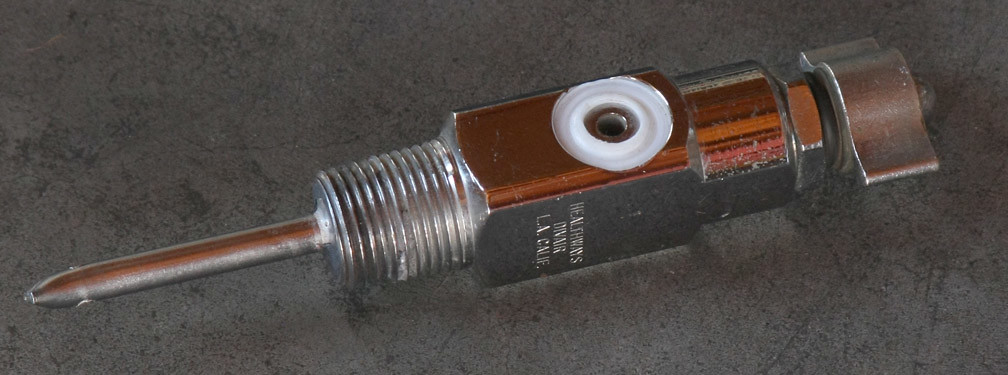

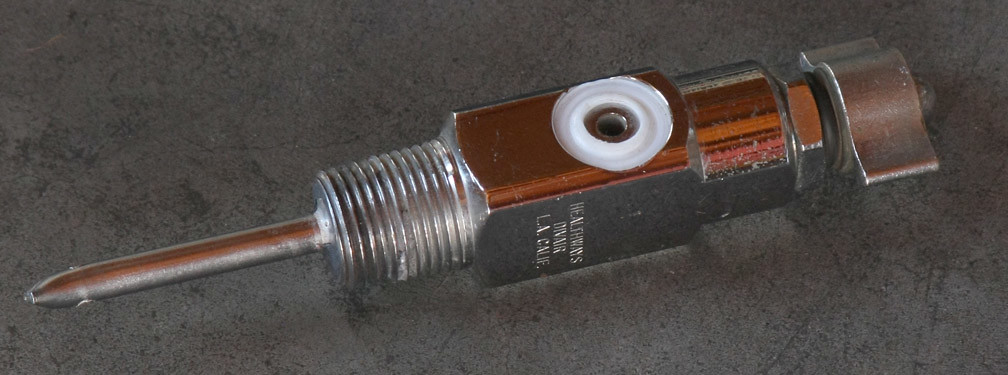

Here the tank valve made for the Divair (I got this from Sitka Dave!): please note the seating surface is not neoprene, but nylon!  JB |

|

|

|

Post by tomcatpc on Jul 23, 2016 14:14:08 GMT -8

Looking forward how this topic turns out.

Is just me and my dyslexia coming out, or does anyone else see the front cover of the Divair looking like an ashtray from the Art Deco era? OK, I'll try and stay on topic.

Mark

|

|

|

|

Post by nikeajax on Jul 25, 2016 10:44:09 GMT -8

|

|

|

|

Post by nikeajax on Jul 25, 2016 11:49:34 GMT -8

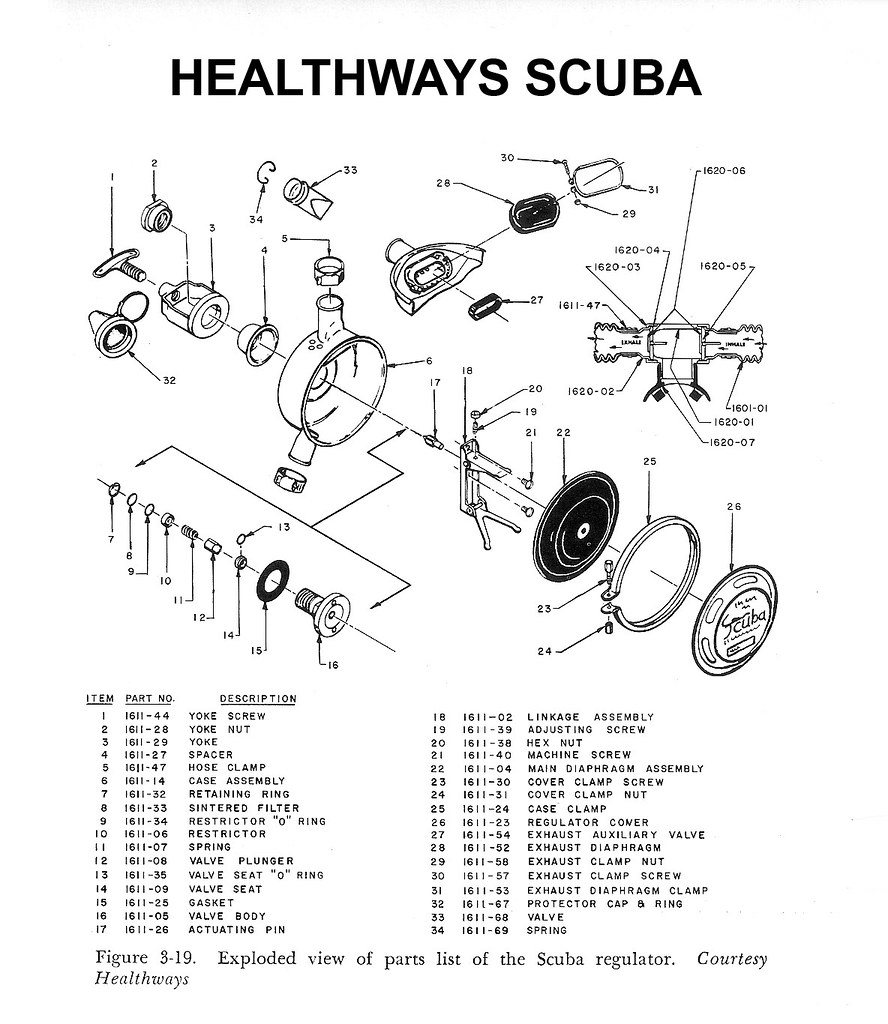

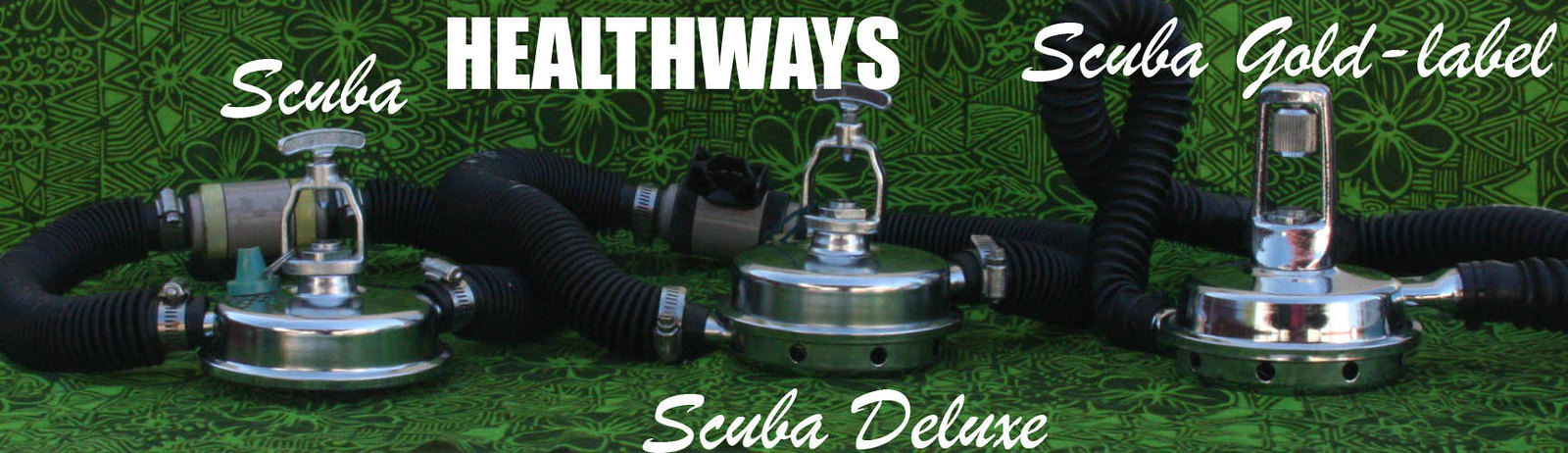

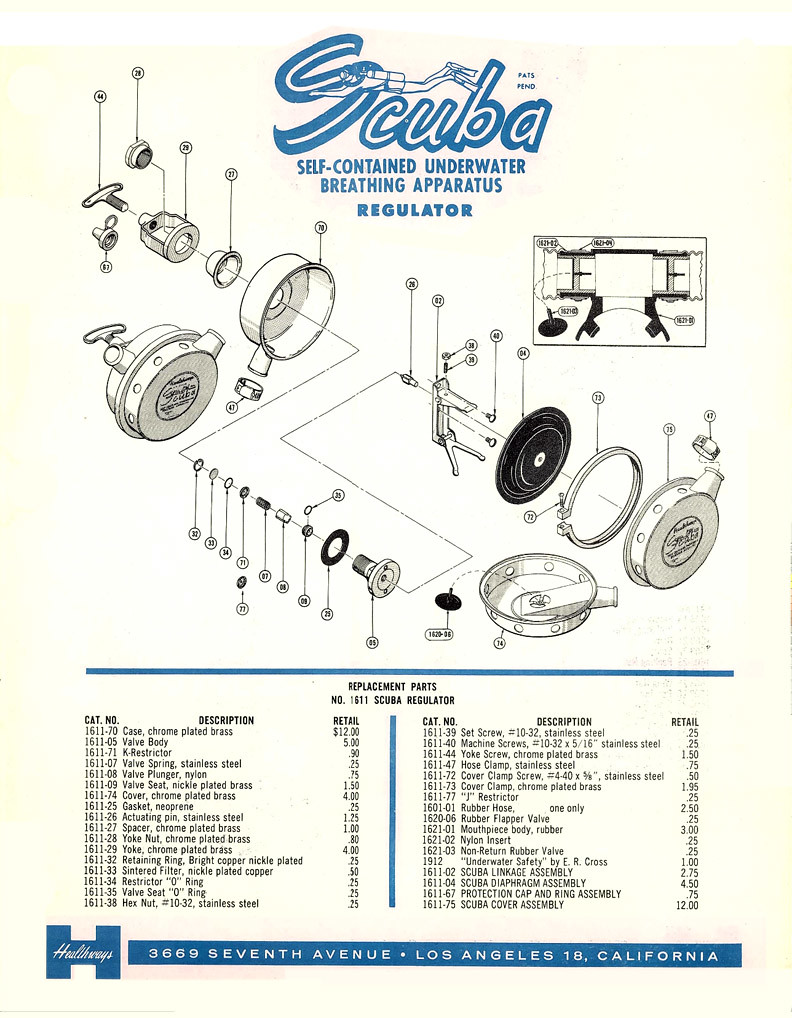

Healthways next regulator was the Scuba in 1957: at this time they had also trademarked the acronym SCUBA, Self Contained Underwater Breathing Apparatus.   Perhaps what made HW regs so innovative, very much like Dacor, is that they were not going to use ideas patented by Aqualung. The Divair and Scuba were truly unique regulators: what made the Scuba innovative was it simplicity and compact design. In the lineup below you can see that the Scuba had a lower profile/silhouette than the later Scubas:  This was done by placing everything in the bottom can, including a unique exhaust system that incorporated a duckbill that was unlike Aqualung's. here are some of John's images showing what I'm talking about, the duckbill: Inside the bottom can, looking at the exhaust cover diaphragm:  Looking at duckbill inside exhaust port with cover diaphragm removed:  The Scuba was also HW's last unit to use the Hope-Page mouthpiece:  JB |

|

|

|

Post by nikeajax on Jul 28, 2016 11:02:27 GMT -8

Next I'm going to talk about two of the three different non-return valves used by Healthways: as can be seen in the first Divair diagram, it too used one, but they are all too rare, and I personally don't know of anyone who owns one! With the introduction of their newly designed regulator, the Scuba Deluxe, Healthways, for some reason, decided to ditch the Hope-Page and use their own lighter weight mouth piece. The problem with this idea was that their new mouth pieces used much smaller 23mm diaphragms, as compared to the HP’s much more efficient 38mm. At the time, the breathing characteristics of SCUBA-regulators wasn’t fully understood by most people. It was thought that a diver was breathing more efficiently if they were working harder to breathe: an excellent example of this is the Dacor “Dial-a-Breathe”, where a diver could dampen the air flow by means of an adjustable vane placed in front of the intake air-horn of the regulator. It wasn’t until the late 1960’s that designers began beefing up the sizes of their exhaust ports. The major problem is the buildup/accumulation of CO2 from the diver’s inability to breathe and exhale naturally. After some sixty plus years, the Hope-Page is still a highly sought after mouth piece for double hose SCUBA regulators because it was designed exceptionally well. Not only does it breathe nicely, the pitch, or diver’s bite, can be adjusted while in use/at depth. Yet another advantage the HP had was that the actual mouth piece could be replaced, unlike the new one, if a diver accidently bit through the bite tabs, the entire mouth piece would need replacing. Conversely; it is not recommended that a diver actually use the Healthways mouthpiece for diving unless the inner baffle, see image, and spider vanes are removed from the nylon inserts: this process makes the non-return aspects of them null and void.   |

|

|

|

Post by broxton coalition on Jul 28, 2016 17:33:18 GMT -8

Thanks JB for creating this post and displaying your regs for us to see. healthways were a serious player in the early scuba game. nice to see a complete product line from a manufacturer. i had heard the first cast bronze divairs were a rare comodity to find and always sold for a steep price.going from bronze to alumimum is just flat out laughable. the salt water just gobbled that reg right up!  still, any of these regs are classics and a great part of dive history. i once read a trivia question by the late kent rockwell that asked "who were the first U.S. scuba manufacturer's?" it was not the divair! first correct answer gets a bronze divair, oooopppp's, did i just say that? edit,edit,edit....call HR immediatly!!!!!!!!!!!!!!!!  |

|

|

|

Post by herman on Jul 29, 2016 2:50:08 GMT -8

If you mean manufacturer as in actually made the parts in a factory, that's easy, Sherwood...they made(fabricated/cast/machined) the regs for a lot of the early brands, only later did they market them under their name.

|

|

|

|

Post by sitkadiver on Jul 29, 2016 6:34:19 GMT -8

If you mean manufacturer as in actually made the parts in a factory, that's easy, Sherwood...they made(fabricated/cast/machined) the regs for a lot of the early brands, only later did they market them under their name. Do we know when that happened? Or is there an article somewhere that states when Sherwood came on the scene? The only reason I ask is because I know Bastion and Blessings stamped the cans for USD and I think Healthways. However, Voit was only sourcing part of their brass components from the US and ultimately did not have enough parts to call the Navy regulator an American made product. Although, I think the Voit Navy reg was assembled in Southern California. If there's a way to find the details I would be very interested. After reading Phil Nyutten'a account of how Aqua Lung called the assembly process an American manufacture, I find it interesting that Voit wasn't able to do the same a mere 10 years later. Sherwood claims, on their website, that in 1955, they already had 30 years of experience manufacturing life support equipment. Anyway, interesting to see if they were all just trying to "out market" each other. |

|

|

|

Post by cnotthoff on Jul 29, 2016 12:01:06 GMT -8

When I was first trained by Sherwood factory staff back in the 80's, they told us that Sherwood is the fun branch of their company. What is now Cramer Decker made the real money manufacturing the valves for propane cylinders. They have also made valves and regulators for all sorts of gas handling applications including medical and welding. Early scuba valves and regs were labeled Selpac. If Jim Fox is still at Cramer Decker, I'm sure he would have the history.

Good Dives,

Charlie

|

|

|

|

Post by nikeajax on Aug 1, 2016 13:05:27 GMT -8

Next in the lineup is Healthways Scuba Deluxe 1960-62. If the DA Aquamaster is the Cadillac of DH regs, then the Deluxe is the Nash Rambler: it's a solid well build, no frills regulator that always gets the job done:  The Deluxe had a redesigned exhaust system and new mouthpiece too.   The new configuration was much more efficient because it used a diaphragm instead of a duckbill. Please not that the direction of the valve body in the above image has been changed in the way it sits in the lower can: it's 90-degrees off of where it was originally designed which is not very efficient. JB |

|

|

|

Post by duckbill on Aug 1, 2016 15:05:34 GMT -8

Here the tank valve made for the Divair (I got this from Sitka Dave!): please note the seating surface is not neoprene, but nylon!  JB Hey, JB. Great thread! The nylon discs predated the o-ringed valves, from what I understand. This was not a Healthways Divair specific feature. |

|

|

|

Post by nikeajax on Aug 1, 2016 15:30:17 GMT -8

DB, from what I've heard, yes, you're right, but I've only seen the ones Sitka-Dave gave me. I would like to cut some neoprene gaskets for it eventually, so I can keep these for posterior, um I mean posterity. Like you, I have a great respect for original gear, but it's nice to be able to flip back and forth between, as close to OEM as I can get and hot-rodded! I try never to irreversibly augment my gear it just doesn't feel legit, and I feel like I'm cheating somehow.

BTW thanks for the positive feedback!

JB

|

|

|

|

Post by duckbill on Aug 1, 2016 15:46:03 GMT -8

Well, those nylon discs don't seal very well anyway. There can't be any substantial nicks or distortion on the interface surface. I have at least one valve with the nylon, but can't recall what brand. I'll try to remember to check and report back after I get back home. Planning to dive Corona del Mar Thursday, where a lady swimmer got bitten by a Great White two months back  I just hope the kelp forests are there for cover this year! 8-12 foot viz doesn't leave me with much reaction time. CHOMP! |

|

|

|

Post by SeaRat on Aug 1, 2016 19:21:49 GMT -8

Duckbill, There was a National Geographic shark video about why the great white sharks are coming further north, into Oregon now, than before, and apparently it has to do with both food availability and water temperature changes. Now, Jaybird probably wants a few more photos here, so here are some of my older ones, showing the differences in the exhaust and cans for the three Healthways SCUBA double hose regulators.  Note the difference between the exhaust diaphragm and the mushroom exhausts used on the second and third generation Healthways SCUBA regs. Note also that the third generation has a small metal tab which prevents the main diaphragm from covering and sealing the exhaust mushroom.  This shows the other view.  This is a closer view of the two different styles of mushroom valves, the left one being an original Healthways, and the other being the one from The Scuba Museum, available today (and I think of silicone). That tab is important, as if you dive the second generation Healthways SCUBA regulator, and dive it without an inhalation non-return valve in the mouthpiece (a way to get it to perform better), the back-pressure on the diaphragm can seal the mushroom valve on the other side, the exhalation side, and you won't be able to exhale through the unit. I found this out the hard way on a dive at High Rocks, and had to get out of the water and change regulators to continue diving. The Gold Label won't do that because of that tab. I solved this problem in the Healthways SCUBA Deluxe by glueing a small stainless nut onto the exhalation port just beyond the mushroom valve. John |

|