|

|

Post by SeaRat on Oct 29, 2016 23:09:01 GMT -8

Can someone explain the purpose of the secondary diaphragm, please? I don't really understand what it does.  If you are talking about this black diaphragm in the SCUBA regulator, that is the primary exhaust diaphragm. It uses air pressure inside the regulator to block the exhalation horn until you exhale. Because water seeps into the horn in a head-down position, Healthways put a duckbill, as a secondary exhaust, into the horn. The regulator actually does not need the duckbill unless you go head-down a lot. A third exhaust valve, which is a rubber band around the horn's drilled holes just above the end (some have this, and some don't) serves as an alternative if the exhaust diaphragm sticks to the horn opening. John |

|

|

|

Post by vance on Oct 30, 2016 9:00:10 GMT -8

That seems extremely complicated for not so much. I understand they couldn't use the USD type duckbill due to patent issues, but the one in the horn seems to be sufficiently different to get around that. At least, it seems they got around it when they installed them. So you could close this big opening with something solid (like silver soldering a cover over it) and just use the duckbill inside the exhaust horn? Not that I will, but they could have made it without all that forming and special diaphragms?

|

|

|

|

Post by SeaRat on Oct 30, 2016 11:37:04 GMT -8

Phil,

I think that at the time, any duckbill in the exhaust was being challenged by U.S. Divers Company as a patent infringement. I actually think that the DivAir did leave off the duckbill on their production regs, even though it is in the patent. Healthways actually came up with a very easy breathing exhaust, probably better than the U.S. Divers Company duckbill of the time (all duckbills are not the same). But in their second generation, Healthways went completely away from the original SCUBA exhaust, and also away from the duckbill itself, coming up with a mushroom exhaust that did the same thing, and was actually more robust than the duckbill.

Yes, you could probably get away from the diaphragm for the exhaust, but then you have a more restrictive duckbill that the original exhaust system. I should also point out that by putting a metal plate across that exhaust area, you will decrease the clearance between the horn's end and the exhaust space (the plate or diaphragm). This would potentially increase the exhalation effort, especially under high breathing rates. The flexible diaphragm is pushed away from the horn significantly, thereby increasing this clearance and making for easier breathing.

John

|

|

|

|

Post by vance on Oct 30, 2016 20:58:25 GMT -8

I wouldn't try to do that, in any case. I was just speculating that you could. Making some kind of diaphragm out of most any fairly robust rubber sheet would be easy enough if necessary. I'd try some sort of coated fabric work glove material, I think.

Thanks for your explanation of the way the diaphragm seals off the exhaust horn. That makes perfect sense, and is an interestingly complex design to get away from duckbills. It's too bad they didn't think of the mushroom solution until later.

But, the second bit....I'm not convinced that the diaphragm can be affected much by the exhale pressure, since the airflow is very unrestricted at the can and would escape through the exhaust holes without allowing much or any pressure to push against that stiff diaphragm. I understand the horn and the duckbill are aimed right at the diaphragm, but without a duckbill pretty much shoved up into the diaphragm pocket, I can't see that small amount of air pressure doing much to expand the diaphragm into the air chamber. Maybe it doesn't need to be much.

Or maybe I just don't know what I'm talking about.....

|

|

|

|

Post by vance on Nov 15, 2016 15:00:29 GMT -8

Here's the completed lineup (minus the duplicates):  All are ready for the pool test. I will be doing a shallow test soon. Phil |

|

|

|

Post by nikeajax on Nov 15, 2016 15:20:33 GMT -8

Phil, congratulations: you're part of an exclusive club, that being you're not just an owner of them, but they work too  JB |

|

|

|

Post by SeaRat on Nov 15, 2016 18:51:24 GMT -8

I wouldn't try to do that, in any case. I was just speculating that you could. Making some kind of diaphragm out of most any fairly robust rubber sheet would be easy enough if necessary. I'd try some sort of coated fabric work glove material, I think. Thanks for your explanation of the way the diaphragm seals off the exhaust horn. That makes perfect sense, and is an interestingly complex design to get away from duckbills. It's too bad they didn't think of the mushroom solution until later. But, the second bit....I'm not convinced that the diaphragm can be affected much by the exhale pressure, since the airflow is very unrestricted at the can and would escape through the exhaust holes without allowing much or any pressure to push against that stiff diaphragm. I understand the horn and the duckbill are aimed right at the diaphragm, but without a duckbill pretty much shoved up into the diaphragm pocket, I can't see that small amount of air pressure doing much to expand the diaphragm into the air chamber. Maybe it doesn't need to be much. Or maybe I just don't know what I'm talking about..... That's a great line up for your Healthways regulators. Now, about that diaphragm. I've found that the best material is not the coated fabric material from gloves, but the thin, nitril gloves used in the chemical industry as an under-glove. These same type of gloves are also now used in the medical departments for biohazards. They are thin, flexible, and tough, allowing them to be used on the exhaust diaphragm area. They seal pretty well, but you need to try them and perhaps use a sealant around the exhaust lip, after putting silicone grease on it (so as to prevent it from adhering to the exhaust lip). Now, one drawback, which can be major, is that if this diaphragm fails, then the regulator becomes non-functional and will not deliver air! So when I dive this combination, I always do it on my set of doubles with my two-posts so that I have a viable second single hose regulator immediately available. Now, what's the advantage of the original Healthways SCUBA exhaust system. Well, first it puts the exhaust about one inch higher than other regulators (including the Healthways Deluxe, Gold Label, and USD double hose regulators), making the exhalation resistance that much easier. I have taken the home-made duckbill out of my Healthways SCUBA hybrid regulator (with the Gold Label innards), and will be diving it again without that second valve. I'll suffer a bit of hose leak of water, but the exhalation resistance is much easier without it than with it.  Now, concerning the air pressure on the exhaust diaphragm, you are operating off an incorrect assumption. The horn does have holes drilled in it, but those are supposed to be blocked by a rubber band around the outside of the horn inside the regulator box. That would make the only exit to be through the large horn opening, and that opening is closed by the exhaust diaphragm. The exhaust diaphragm reacts to pressures on both sides, from air pressure inside the regulator box, and by air pressure from the exhaled air from the right exhaust hose. Because the main regulator diaphragm is below the exhaust diaphragm (center to center), the air pressure on inhalation is usually (except in a head-down position) higher than the exhaust air inapside the left hose, and therefore is held closed. But as soon as the diver exhales, this pressure reverses, and opens the exhaust diaphragm. I will put together a drawing that illustrates this principle, and maybe Jaybird can make one of his wonderful formal drawings to illustrate this principle for the original SCUBA exhaust design. John |

|

|

|

Post by nikeajax on Nov 16, 2016 11:38:31 GMT -8

I will put together a drawing that illustrates this principle, and maybe Jaybird can make one of his wonderful formal drawings to illustrate this principle for the original SCUBA exhaust design. John John, I am more than happy to obleeg (oblige): please PM me with your requirements! JB |

|

|

|

Post by SeaRat on Nov 16, 2016 11:40:30 GMT -8

Jaybird, I'll take a few photos first, then put together a drawing you can work with. By the way, here's a closeup of the interior of the Healthways SCUBA hybrid, with a glove material cut out and used as an exhaust diaphragm (actually, more of a membrane).  This photo (below) illustrates the rubber band over the exhaust holes. These holes were meant as a third way for air to escape if the exhaust diaphragm got "stuck" against the exhaust tube opening.  By the way, this is a regulator which never existed; I made it by incorporating the original Healthways SCUBA box system with the third generation Healthways Gold Label innards. John |

|

|

|

Post by nikeajax on Nov 16, 2016 12:31:51 GMT -8

PROCESSING... PROCESSING... PROCESSING... PROCESSING... PLEASE STAND BY...

|

|

|

|

Post by SeaRat on Nov 16, 2016 12:40:01 GMT -8

Here's how I use my Sherwood duel post manifold to test out concepts that might be hazardous, such as the glove-membrane exhaust diaphragm on the SCUBA hybrid regulator in open water. Top view:  Front view:  A better photo of the use of the rubber bands to cover the holes in the exhaust tube:  Note also that I have put a mushroom valve into the hose to keep water out of the exhaust hose when in a head-down position. This proved unnecessary, and I have used a glove's thumb as a "duckbill," a modified duckbill (cut down), and no auxillary valve at all at times in my experiments. And here's my photo of my Healthways SCUBA regulator (not the hybrid) broken completely down.  And, a close-up of the Healthways SCUBA can with both the rubber band and the original exhaust diaphragm.  John |

|

|

|

Post by nikeajax on Nov 16, 2016 14:34:18 GMT -8

|

|

|

|

Post by vance on Nov 19, 2016 9:15:26 GMT -8

Or maybe I just don't know what I'm talking about. John Brother, that's the story of my life!  |

|

|

|

Post by vance on Nov 22, 2016 10:07:16 GMT -8

Yeah, the double exhaust valve concept had me confused. The effort they put into the exhaust diaphragm and all the sheetmetal work it required didn't make any sense to me, given there is a duckbill in the horn. I understand what they were trying to do and why after all the 'splainin'. I also understand why they abandoned it so quickly.

A good silicone duckbill could have all of us "Scuba 1.0" enthusiasts diving them without leakage problems and no inner tubes would have to be harmed! It really doesn't seem like it would be that hard to make one....

|

|

|

|

Post by SeaRat on Dec 19, 2016 18:35:38 GMT -8

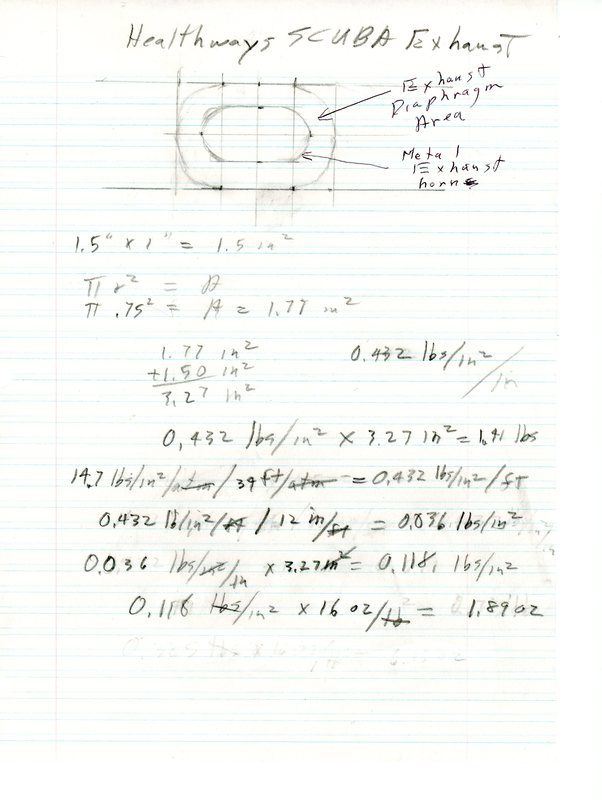

Okay, I'm going to try explaining this exhaust system a bit better, as it is pretty unique. Take a look at this photo:  You will note that the exhaust tube extends inside the regulator housing. This tube is also flush with the rim of the exhaust diaphragm opening, which has a "bubble" in it to allow it to be pushed by air pressure against the exhaust tube inside. I decided I wanted to figure out how much pressure it put onto the exhaust diaphragm, so I made a calculation. Here's my worksheet:  If you'll look at the worksheet, I calculated the area by using the measurements, and deciding that the two rounded areas are actually the area of a circle, while the rectangular areas can easily be calculated using the area of a rectangle. So the circular areas are about 1.77 square inches, while the rectangle is about 1.5 square inches. Added together, that gives an area for the exhaust diaphragm of 3.27 square inches. Now, water exerts 0.432 pounds per square inch for each foot of depth in fresh water (for salt water, it's 0.445 pounds per square inch). If there were a difference of one foot, that number of 0.432 pounds per square inch times the area of the diaphragm, 3.27 square inches, would equal 1.41 pounds exerted against the diaphragm. But it's not a full foot of water pressure, but rather about an inch of water pressure difference between the center of the diaphragm and the exhaust tube. So if we look at t he 0.432 lbs/in2/ft divided by 12 inches/ft = 0.036 lbs/in2. Multiplying 0.036 lbs/in2/inch times 3.27 square inches equals 0.118 lbs/square inch. But we sometimes think in terms of ounces rather than pounds. So multiplying 0.1189 pounds per quare inch times 16 ounces per pound equals 1.89 ounces of force applied against that flexible diaphragm. So in effect, you have a greater-than 1.5 ounce piece of lead on top of that diaphrigm pushing the flexible membrane against the exhaust tube. So what Healthways did was to make an exhaust system that used air pressure to press the diaphragm against the exhaust tube, with the equivalent of 1.89 ounces of force. That is enough pressure to seal that exhaust. But because of some balance problems in different attitudes (diver's orientation in the water), theoretically some water will enter into the exhaust tube/hose when the diver is in a head-down position, so Healthways placed a small duckbill into the tube as a second line of defense against this "imbalance." Yesterday, I made a pool dive after my dive on the Scubair (see the Healthways Single Hose thread) using my Healthways hybrid SCUBA regulator to do further tests of this exhaust. I have said before that the duckbill was mostly unnecessary for diving this regulator (original Heathways SCUBA regulator). Yesterday, I dove it without the duckbill backup in the exhaust tube. For regular swimming underwater, the regulator functioned very nicely. I had no water intrusion into the exhaust tube. I even did a short surface dive (the water was only 18 feet deep), and had maybe a little intrusion of water, but nothing really predominant. I then did a ditch and don of the unit, and before donning it watched the exhaust as I was breathing on it. The tank was in front of me, with me behind the tank breathing. I could watch the exhaust, and when I breathed normally the air exited in only the top part of the case holes. When I exhaled forcibly, it used most to all those holes, but I did not feel a resistance. I then tipped the tank/regulator on its side so that it was horizontal, and felt no effect. I then tipped it upside down, where the water should be entering the exhaust tube, and felt felt only a small amount coming in, and being exhaled with each breath. I was getting low on air, and so started swimming toward the ladder to get out (I used this tank for regulator breathing experiments in my garage, so it was not full at the start). So this confirms that the exhaust really doesn't need the duckbill, but it is a convenience for keeping the exhaust tube completely dry. Unfortunately, it also adds some breathing resistance to a very nice breathing exhaust. Now, I did not tell you about what happened between the two dives. I was topside and had just put the hybrid SCUBA regulator onto the tank, and put the unit on when I saw that the other two divers had gotten out of the water. I went over and talked to them. There was a man and a young lady diving, in modern gear. The older man said to me, "I can tell an old-timer diver when I see he's not wearing a BC." I said that normally I do wear my own design BC, but forgot it today. He then told me that the young lady was on her first dive, trying to determine whether she could take dive lessons. She had not freaked out,and so was going to start a diving course. The older guy was her instructor. I told her that I had been diving since 1959, and "Being weightless underwater was wonderful." So maybe we have a new diving coming into the fold. John |

|