|

|

Post by snark3 on Jul 30, 2018 14:16:33 GMT -8

Thanks JB. This Flickr stuff is new to me.

|

|

|

|

Post by nikeajax on Jul 30, 2018 14:19:11 GMT -8

That's why I'm here my friend  We need to keep our sport safe...  JB |

|

|

|

Post by snark3 on Jul 30, 2018 14:25:44 GMT -8

Safe is always good. When I'm done with this one I've got a few more "oldies but goodies" to see if I can get working. I have a couple of Snark3s and a couple of Northills.

Thanks again

|

|

|

|

Post by nikeajax on Jul 30, 2018 14:56:38 GMT -8

...and a couple of Northills. Thanks again Dude--you totally stink! I don't think I like you no more...   Those are really dangerous, you'd better give them to me... That's one I don't have, grumble, grumble, grumble... SIGH! JB |

|

|

|

Post by vance on Jul 31, 2018 9:08:42 GMT -8

On this diaphragm, the spring goes over the nut side, and the pin sits against the flat button. The button on the right in Skip's picture looks a bit thicker, with the raised section. My spare diaphragm (HTII) has that raised part. The raised part on mine seems to be .05" high? There's a bit of a dimple where the pin contacts it. The other diaphragm's button also looks like it might have a dimple as well.

The raised one would probably work, if the adjuster can be backed out enough to make up the extra thickness.

|

|

|

|

Post by snark3 on Aug 1, 2018 13:40:53 GMT -8

Today I put the diaphragm with the "top hat" in my reg body. Because the "top hat" style is thicker at the base it won't allow the diaphragm to contact reg body. I've decided to try to use some silicone grease on the old one and see how I make out.

|

|

|

|

Post by snark3 on Aug 16, 2018 2:55:48 GMT -8

This morning I tried to check the IP on my NED 2 hose. The IP goes to 240, pops the second stage, leaks down to about 160 then seals up tight. I tried adjusting the spring on the HP diaphragm, no matter which way I go it does exactly the same thing. Obviously I've got a problem somewhere. Can anybody point me in the direction to start looking. Thanks

|

|

|

|

Post by SeaRat on Aug 16, 2018 4:34:23 GMT -8

Does it stay at 160 psig? You can breathe off it and it stays there?

John

|

|

|

|

Post by snark3 on Aug 16, 2018 4:52:04 GMT -8

John

It stays at around 240 with the second stage leaking as long as the air is on. When I turn the valve off on the tank it leaks down to about 160 and stays there. The tank I'm using is a steel 72 (2250 PSI) with about 1700 psi in it.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Aug 16, 2018 7:02:19 GMT -8

John It stays at around 240 with the second stage leaking as long as the air is on. When I turn the valve off on the tank it leaks down to about 160 and stays there. The tank I'm using is a steel 72 (2250 PSI) with about 1700 psi in it. Sounds like the IP spring is either not the correct one, or the distance between the mushroom cap and the IP diaphragm is compromised. It also could be the small pin that connects the mushroom cap to the HP seat is too long.......... If you have another NED, compare the pin, spring and cap of each......don't gettem mixed up. Pull the IP adjusting/retaining nut and observe the rubber diaphragm.....if it has a significant bump in the center, the pin maybe too long pushing the cap up or the cap has some interference holding it too high. Compare the IP springs.....if the offending one is taller than the other.......probably not the correct spring. Should be the same length, wire dia. ID and number of coils. Hope this helps. |

|

|

|

Post by nikeajax on Aug 16, 2018 7:27:05 GMT -8

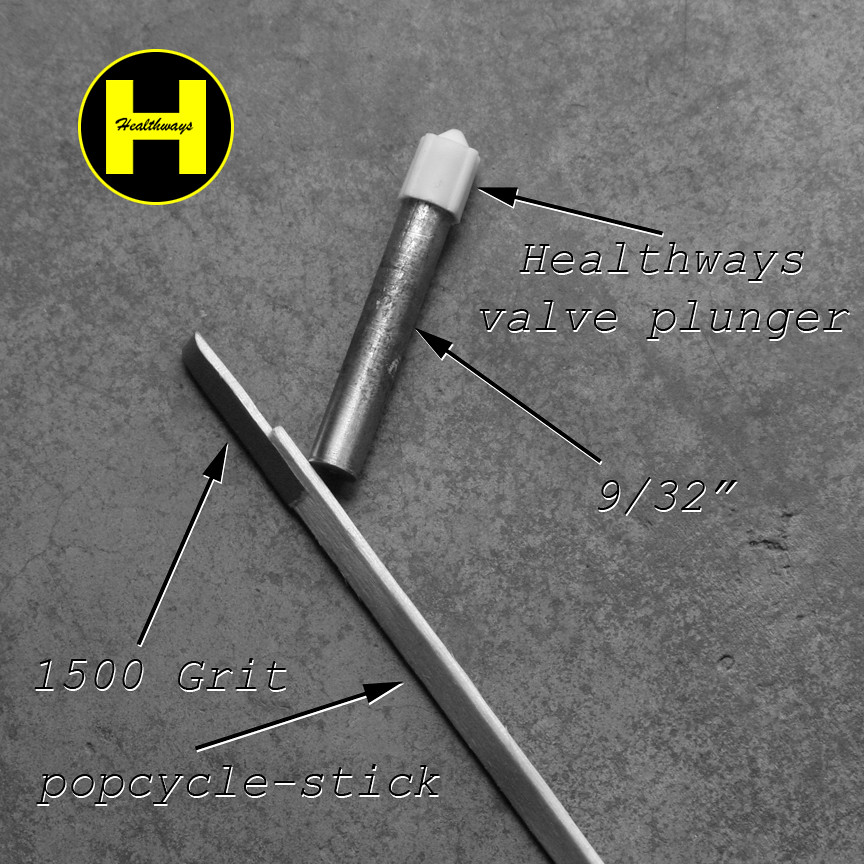

Hmmmmm? Sounds like the valve-plunger to me... They can be fixed too:  Or, if you have the newer type, just lock the shaft into a drill chuck and spin away: please note that I have the diameter wrong on my illustration. JB |

|

|

|

Post by SeaRat on Aug 16, 2018 7:35:59 GMT -8

If this NED regulator is actually the same as the Hydro-Twin II, the valving is different than what Jaybird is showing. The Hydro-Twin II is a balanced first stage, with a different HP seat.

John

|

|

|

|

Post by nikeajax on Aug 16, 2018 7:50:22 GMT -8

John, yes, but, the seats are the same and the tip of the valve plungers are the same: the same technique applies to both. One needs a holder-onner (steel shank), wheres the newer type has its own holder-onner. Both can be locked into a drill and spun up to resurface the end...  JB |

|

|

|

Post by snark3 on Aug 16, 2018 9:18:41 GMT -8

Thanks for all the ideas guys.

JB- I was able to source a NOS plunger, which is what I'm using. I know that doesn't guarantee it's not the problem but I doubt the plunger itself is the problem. Technician error...……...possibly

John- this is actually a Hydro-twin I the unbalanced version so it's the same as what he's showing but again mine is NOS.

Ol' Mossback I don't have another to compare it to but I'll review this thread and see if anyone posted pics that I can compare mine to the pics posted.

Thanks again guys

|

|

|

|

Post by nikeajax on Aug 16, 2018 12:01:01 GMT -8

Snarky, my wife's Conshelf would do something very similar to what you're describing: the problem went away as soon as I replaced the valve soft-seat/plunger. Try doing a resurfacing on your old one. BTW you don't need to hold it on for more than two or three seconds!

The Connie would do a very loud splutter-pop before locking up with very high IP.

Also, try flipping your valve seat: it could be nicked! It doesn't take much to do what you're describing--SIGH! Before removing, use a Sharpie to mark it, that way you know exactly which side is which, and you may not be able to tell which is which once you get it out: all cats are black in the dark!

JB

|

|